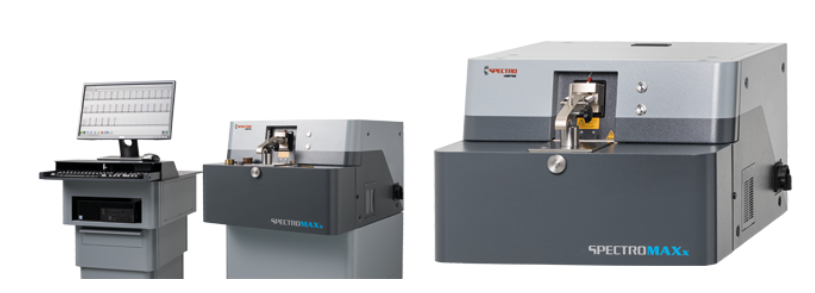

Products

SPECTROMAXx

Analytical enhancements and more for next-generation leadership in metal analysis

OVERVIEW:

- iCAL 2.0's unique sample standardization helps maintain consistent standardization regardless of most temperature changes, saving an average of 30 minutes per day.

- Detection limits improved by 30% to 40% compared to its predecessor (example: iron, aluminum, and copper base)

- Up to 64% less argon consumption in standby mode, compared to previous models

- Ideal for routine and accurate analysis of all incoming and outgoing materials and for process control (including nitrogen) in foundries: covers 10 matrices, 65 methods and 59 elements.

From incoming materials to in-process testing and final quality inspection, metal production and manufacturing plants demand advanced elemental analysis. For more than a decade, one instrument has routinely provided just that. Its track record of reliability has made SPECTROMAXx one of the industry’s best-selling arc/spark optical emission spectrometry (OES) analyzers. Its fast, accurate, and cost-effective measurements provide essential security in critical supply chains around the world. Like its predecessors, this 10th-generation SPECTROMAXx (LMX10) delivers exceptional speed. Users gain ultrafast insights and can react quickly to changing process conditions. It also offers a dramatically reduced cost of ownership, with fewer consumables, advanced diagnostics, and simple maintenance to increase availability and prevent costly downtime. The 10th-generation SPECTROMAXx features all-new factory calibrations, with expanded calibration ranges and element selection; optimized source excitation parameters; and improved limits of detection (LOD). For example, for iron, aluminum, and copper matrices, the analyzer improves its already impressive performance with 30% to 40% better levels of detail (LOD). It offers truly intuitive operation thanks to the use of buttons on the toolbar, a user management system, and a clear separation between operation and instrument programming. Measurement is controlled using clear symbols and buttons on the toolbar. Once a workflow is started, only the logical functions at any given time will be active in the control software; all other commands remain hidden. With application profiles, customer-specific information can be configured before starting operation, freeing lab technicians from administrative tasks. The SPECTROMAXx arc/spark OES metal analyzer independently monitors all operating parameters. It dynamically determines the required measurement time based on sample properties and even shows when the spark gap needs to be cleaned depending on the type of sample being examined. The optional SPECTRO PROTEKT Global Remote Monitoring Service protects your analyzer's performance and productivity by continuously remotely monitoring warning and error messages generated by key components of your instrument.